Industrial pipes are often overlooked but are critical components of modern manufacturing facilities. These systems form the backbone of many processes, enabling the seamless transfer of liquids and gases. This blog explores all the key aspects of industrial piping systems so you can better understand their role in modern manufacturing.

The Vital Features That Drive Efficiency

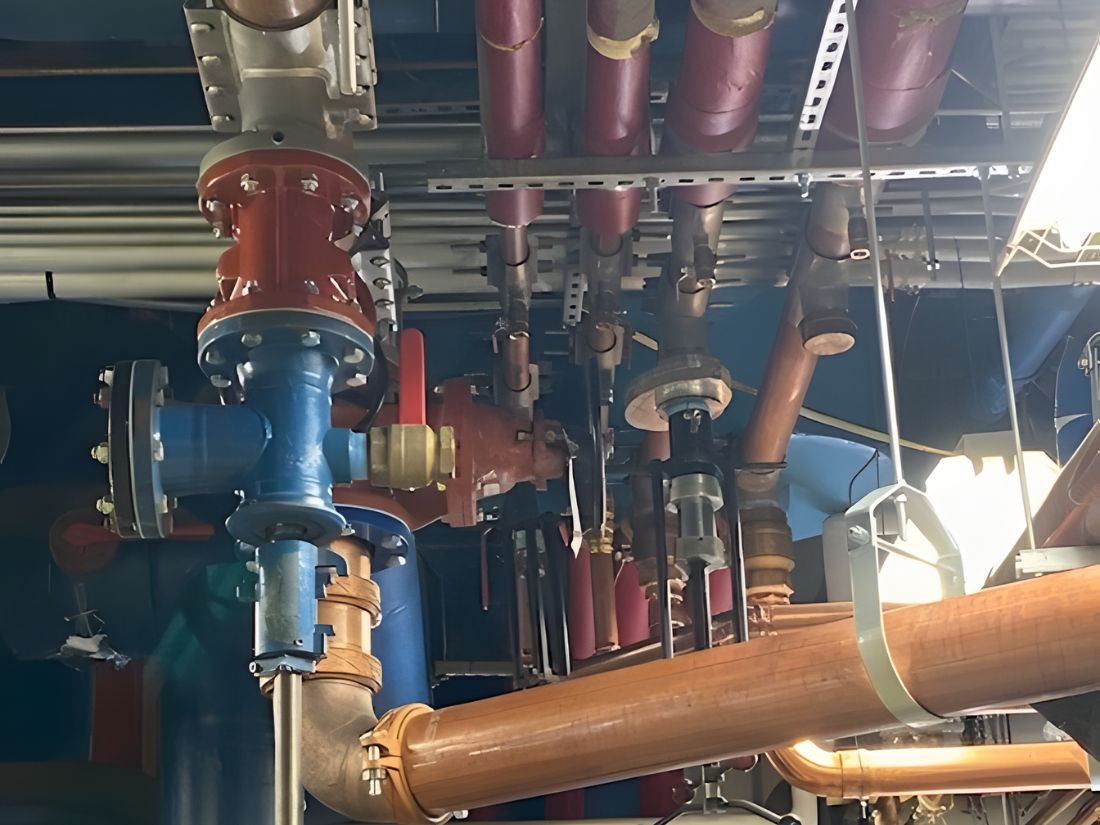

Industrial piping systems are designed to handle high temperatures, pressures, and corrosive substances while maintaining efficiency and safety. Their durability and material diversity—from stainless steel to PVC—make them ideal for meeting the varied needs of manufacturing plants. Precision engineering ensures leak-free connections, minimizing downtime and enhancing productivity. Additionally, these systems are customizable, allowing manufacturers to optimize layouts for maximum operational efficiency.

A Wide Range of Applications

The role of industrial pipes in modern manufacturing can vary quite a bit depending on the application you’re referring to. Food and beverage plants rely on hygienic piping systems to transport liquids like milk, juice, or water without contamination. Chemical manufacturers use pipes capable of withstanding harsh, corrosive substances during production and transport. Meanwhile, in automotive or aerospace manufacturing, cooling pipes dissipate heat generated by heavy-duty machinery to maintain operational safety. Even the pharmaceutical industry depends on ultra-sanitary piping systems to meet stringent regulatory standards, ensuring the safe production of medications and vaccines.

Keeping Pipes in Peak Condition

Maintenance is a critical aspect of ensuring piping systems perform effectively over time. Regular inspections can identify early signs of corrosion, cracks, or blockages, preventing catastrophic failures. Cleaning protocols—especially for food-grade or pharma-grade pipes—ensure product purity while extending the system’s lifespan. It’s also essential to monitor pressure and temperature levels, as exceeding system thresholds can reduce reliability. If things become too bad, you might need to look for some process piping services that can get into your system quickly and efficiently to fix whatever has gone wrong.

Innovations Paving the Way for Tomorrow

Industrial piping systems are evolving with technological advancements. Smart pipes embedded with sensors now allow for real-time monitoring of flow rate, pressure, and temperature, endlessly improving safety and efficiency. Meanwhile, sustainable piping materials are gaining traction, emphasizing recyclability and reducing the environmental footprint. On top of that, automation and AI integration into piping systems promise to revolutionize scheduling, leak detection, and maintenance planning. For manufacturers, these advancements mean downtime will decrease, and performance will soar.