In the vast infrastructure of industrial pipelines, ensuring a smooth and continuous flow of the transported goods is essential. Enter the pipeline pig, a piece of equipment that passes through pipes while preserving the integrity of a pipeline network. If you are unfamiliar with this item, you’re in luck. We are about to take a deep, detailed plunge into the world of pipeline pigging, covering what it is, how it works, and some other important details about the process.

Unraveling the Importance of Pipeline Maintenance

When we talk about the flow of refined products, water, or gases through pipelines, we envision a seamless, uninterrupted process that operates like clockwork. However, reality paints a different picture. Over time, pipelines are susceptible to a variety of issues, from sediment buildup to internal corrosion, that can impede the efficiency of a pipeline, disrupt operations, and pose safety hazards.

For industries that rely on the smooth functioning of their pipelines, such as water treatment and chemical plants, investing in pipeline maintenance is a business imperative. However, you’ll likely not want to shut down your operations to perform this type of maintenance if you don’t have to. This is why many qualified pipeline maintenance services utilize pigging to work on pipelines and keep them in working condition.

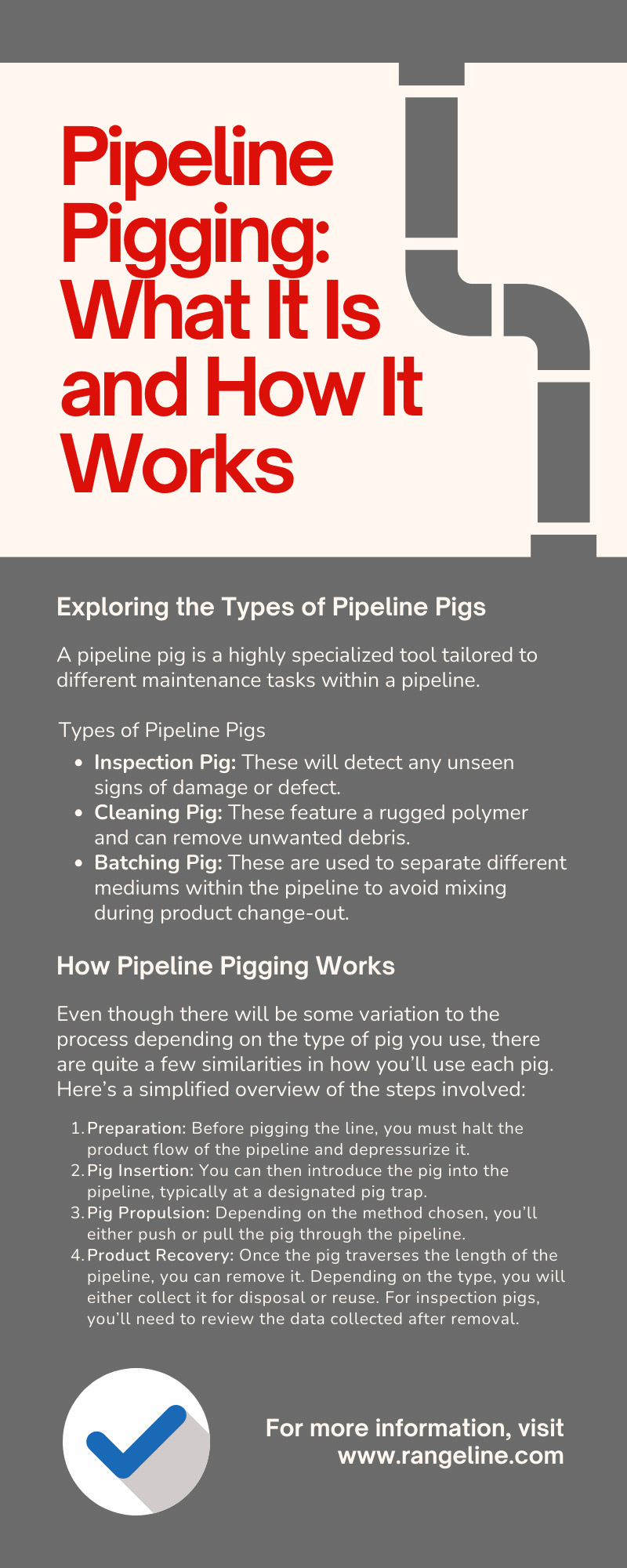

Exploring the Types of Pipeline Pigs

A pipeline pig, also known as a pipeline intervention gauge, is the farm animal you might initially picture. It’s a highly specialized tool tailored to different maintenance tasks within a pipeline. Each type serves a different purpose, so we will cover each one for you here.

First off, we have inspection pigs. These have built-in sensors and cameras that allow you to inspect the interior of the pipeline without having to open it up. These pigs will detect any unseen signs of damage or defect, allowing you to know about them before they become operational issues.

Next, we have cleaning pigs. These tools feature a rugged polymer and can remove unwanted debris, such as rust and mill scale, that could have accumulated on the sides or bottom of the pipeline. These are crucial for regular pipeline maintenance.

The last type of pig is the batching pig. Used to separate different mediums within the pipeline to avoid mixing during product change-out, these pigs serve a more niche use case. They are quite effective at displacing liquids and filling your pipeline with water when needed.

How Pipeline Pigging Works

Now that you know the types of pigs, it’s time to learn about how the pigging process works. Even though there will be some variation to the process depending on the type of pig you use, there are quite a few similarities in how you’ll use each pig. Here’s a simplified overview of the steps involved:

- Preparation: Before pigging the line, you must halt the product flow of the pipeline and depressurize it.

- Pig Insertion: You can then introduce the pig into the pipeline, typically at a designated pig trap.

- Pig Propulsion: Depending on the method chosen, you’ll either push or pull the pig through the pipeline.

- Product Recovery: Once the pig traverses the length of the pipeline, you can remove it. Depending on the type, you will either collect it for disposal or reuse. For inspection pigs, you’ll need to review the data collected after removal.

Applications in Different Industries

The best part of pipeline pigging is that it can be a universal practice, which is why many sectors have adopted it. One of the most common ones to utilize this method of pipeline maintenance is the oil and gas industry. Companies use these tools to clean pipelines, perform in-line inspections, and inspect welds for integrity.

Pigs also play a significant role in the water treatment industry in regards to the distribution of water. They do this by helping to maintain water quality by cleaning and inspecting potable water pipelines, ensuring citizens receive a clean and safe supply.

Chemical plants are another sector that relies on pigging to ensure that different chemical products are not contaminated. They also use pigs to clean the lines between each use, preventing unexpected reactions.

Best Practices for Effective Pipeline Pigging

Engaging in pipeline pigging is not just about running the pigs through the lines—there’s a method to the maintenance that will lead to more effective results. First, make sure you adhere to a regular maintenance schedule. Consistency is key. Whether daily, weekly, or monthly, regular pigging ensures that the pipelines remain free of obstructions and nipping any developing issues in the bud.

Also, make sure you choose the right pig for the task at hand. This applies to both type and size. The wrong pig could fail to clear the pipeline effectively or, worse yet, become stuck in the line, leading to significant downtime. After pigging, you should always evaluate your pipelines by testing them to ensure the process achieved the desired results. By following these best practices, industrial businesses can maintain a high level of operational readiness and reliability in their pipeline systems.

The Future of Pipeline Maintenance

Now that you understand what the pipeline pigging process is and how it works, we need to look toward the future of what this technology could potentially do. With advancements in material science and sensor technologies, the future of pipeline maintenance is looking brighter. Intelligent pigs with artificial intelligence and IoT capabilities are emerging, promising more detailed and real-time data about the health of a pipeline.

Furthermore, robotics technology is on the rise, with the potential to handle more complex tasks in challenging conditions, such as offshore or subsea pipelines. Companies are investing in robotic pigs capable of repairing defects within the pipeline, further reducing the need for human intervention in hazardous scenarios. Looking ahead, experts foresee a future where these smart pigs will patrol, clean, and repair pipelines—a potential that excites cutting-edge technology enthusiasts and countless global industries. It will be interesting to see how this process further develops in the years to come.