Any city or municipality utilizes a complex array of pipelines to distribute energy, water, and other resources to your home, businesses, and public services. Pretty much every aspect of society relies on these pipelines. For that reason, services like wet tapping are crucial to maintaining and repairing pipeline systems. To help understand the potential risks pipelines face, here are a few things that can cause water main breaks.

Time and Materials

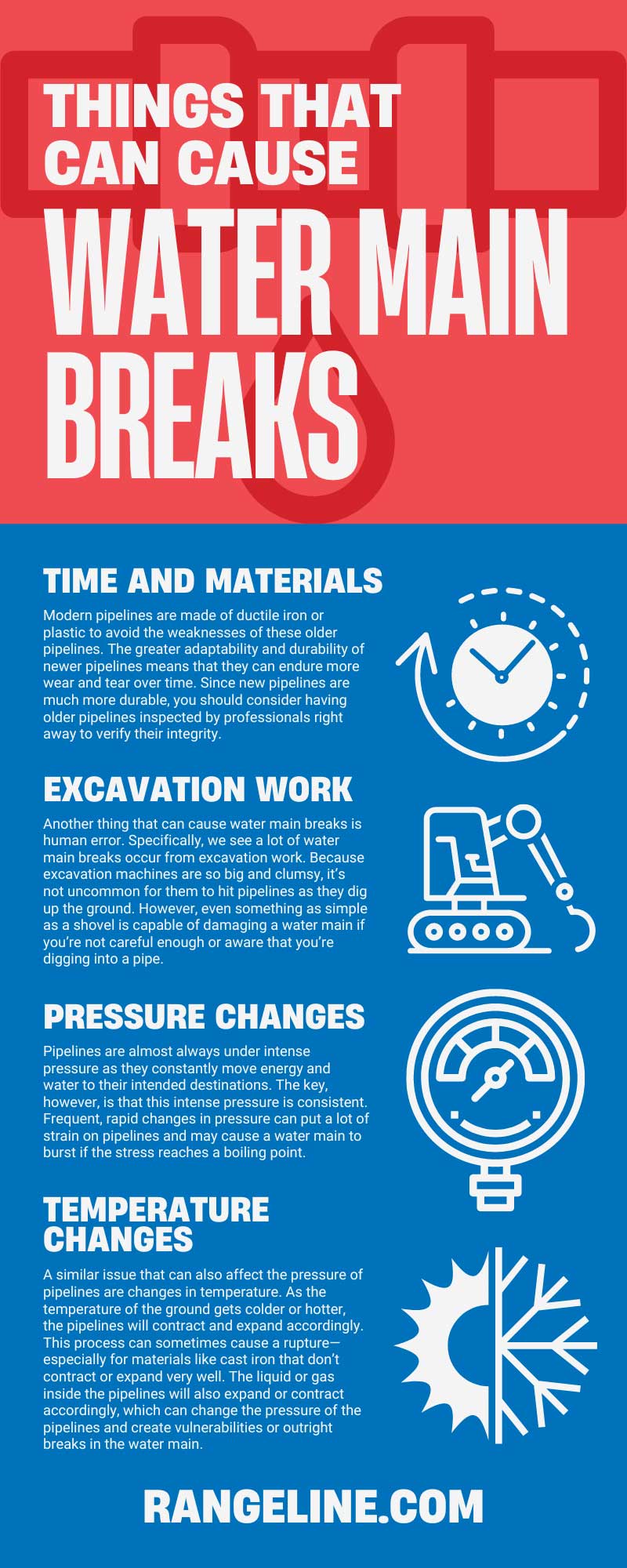

Time, wear, and tear are the enemies of all things, and pipes are no different. Over time as pipes get older, water mains are increasingly more at risk of breaking or bursting. The material the pipes were made with can also affect how much time the pipes can endure before giving out. For example, most water mains created before 1980 were crafted from cast iron or concrete pipe, which can become brittle with time. Furthermore, because cast iron doesn’t contract or expand very well, it’s very susceptible to changes in temperature.

Modern pipelines are made of ductile iron or plastic to avoid the weaknesses of these older pipelines. The greater adaptability and durability of newer pipelines means that they can endure more wear and tear over time. Since new pipelines are much more durable, you should consider having older pipelines inspected by professionals right away to verify their integrity.

Excavation Work

Another thing that can cause water main breaks is human error. Specifically, we see a lot of water main breaks occur from excavation work. Because excavation machines are so big and clumsy, it’s not uncommon for them to hit pipelines as they dig up the ground. However, even something as simple as a shovel is capable of damaging a water main if you’re not careful enough or aware that you’re digging into a pipe.

To prevent this, proactive research and cautious construction are highly advised when digging into the ground within a municipality. Remember that even your own backyard has pipelines running through it!

Pressure Changes

Pipelines are almost always under intense pressure as they constantly move energy and water to their intended destinations. The key, however, is that this intense pressure is consistent. Frequent, rapid changes in pressure can put a lot of strain on pipelines and may cause a water main to burst if the stress reaches a boiling point.

A good example is fire hydrants. If they’re opened or closed too quickly, the pressure changes too rapidly and can greatly stress the pipes as they try to compensate. In particular, a pressure surge is a phenomenon referred to as a “water hammer” because it sends a high-pressure shockwave through the piping system.

Temperature Changes

A similar issue that can also affect the pressure of pipelines are changes in temperature. As the temperature of the ground gets colder or hotter, the pipelines will contract and expand accordingly. This process can sometimes cause a rupture—especially for materials like cast iron that don’t contract or expand very well. The liquid or gas inside the pipelines will also expand or contract accordingly, which can change the pressure of the pipelines and create vulnerabilities or outright breaks in the water main.

Ground Settling

One of the most complex causes for water main breaks is when the ground settles. This is a hard thing to account for, as the soil beneath a building’s foundation shifts naturally over time. As the soil settles, it can put more and more stress and pressure onto the pipelines until a crack eventually occurs and the pipe leaks or bursts.

For areas with a risk of ground settling, there are some measures to try and prevent it. Landscaping can help improve the drainage of an area, as abundantly marshy and muddy ground is likely to sink and shift more. If the issue is needing a firmer foundation, clay-rich soil is firmer and can be placed around the pipelines to prevent the soil above from progressively getting heavier and adding more stress.

Corrosive Soil

Similarly, the soil around a pipe can become corrosive and begin eating away at the pipes depending on their material. This is especially common in metal pipes like iron, and corrosion typically affects fittings and other vulnerable spots on these types of pipelines. Eventually, the corrosion weakens the pipe to the point where it bursts.

Polyethylene encasement is the recommended and most popular method of protecting pipes from corrosion and harmful acidic soil, as it’s both effective and inexpensive. However, some municipalities may instead opt to make their pipes out of non-corrosive materials like C-900.

Reacting to Breaks

So, what do you do when a pipeline leaks or a water main outright breaks and bursts? Pipelines require a certain expertise to be handled and repaired properly. Shutting down an entire pipeline is typically not an option, as it’s no exaggeration that pipelines are being used around the clock year-round. For that reason, you need a service capable of providing services like hot and wet tapping or line stopping and line freezing to repair the damage while redirecting the flow of energy or water. Such experts can ensure that the pipe systems continue to function even while undergoing maintenance or construction.

For preventative maintenance, water main condition surveys are a good way to identify potential issues early on. To assess the condition of your pipes, engineers research the physical, operational, and environmental factors to get a sense of how at risk a water main may be and what can be done to best maintain or replace the pipes.

For professional assistance and servicing, always rely on Rangeline Group. We’re well-versed in a variety of tapping and pipeline services and products. We’ll ensure that your pipes are at their best or replaced with the best materials without ever interrupting daily operations. We understand that modern society expects water and power to be provided on demand, so we’ll do our best to ensure no one ever goes without it!